We Got A Behind-The-Scenes Of This Impressive American Manufacturing Business

A big chunk of the off-road industry dwells in the western portion of the US. The closer you get to the coast, the more companies you’ll see. California, especially the southern part, has one of the largest concentrations. That said, off-roading as a hobby has exploded over the last decade.

Backwoods Adventure Mods stands out. Not just in product design and approach, but by location. These guys are centered in northwest Arkansas in Springdale – right outside the Ozarks. It’s neat to see the industry spreading its legs.

Last fall, on our way to the Express Rally Overland Ozarks event, we stopped by for quick tour of the facilities to see it in person and meet the team.

Find Them Online

Background

Backwoods embodies what an overland accessory company should be. With decades of manufacturing experience in several industries, they first penetrated the market with their extension van product lines. We’re talking complete line ups for models like the Sprinter and Transit vans. Bumpers, roof racks, storage systems and more.

At this point, they’ve been pushing hard into SUVs (like the 4Runner) and trucks (like the Tacoma..) for a few years. They’ve grown fast while producing great content and putting their armor and more to the test. I personally run their front and rear bumpers. More on that later.

The core focus for the brand is using steel where it’s most needed, while substituting aluminum where weight savings is important. This hybrid metal material model can save around (or even over) 50 pounds, for example, with a front bumper. Their no bull bar front bumper system only weighs 80 lbs.!

Tech Capabilities

Before I stopped at Backwoods, their facility was explained to me over the phone. And while I understood that it was a solid operation, until I saw it in person, I didn’t realize how extensive it really was. What they’ve built over the years is really impressive. And I mean that.

Utilizing a combination of all sorts of leading tech, the process is dialed. And supported in a wide variety of ways. One example is seen above. There are several robots putting in hard work, and allowing human hands to work where they’re most needed. The robot above is welding van storage cabinets. In a very quick and precise way – down to moving the units into position.

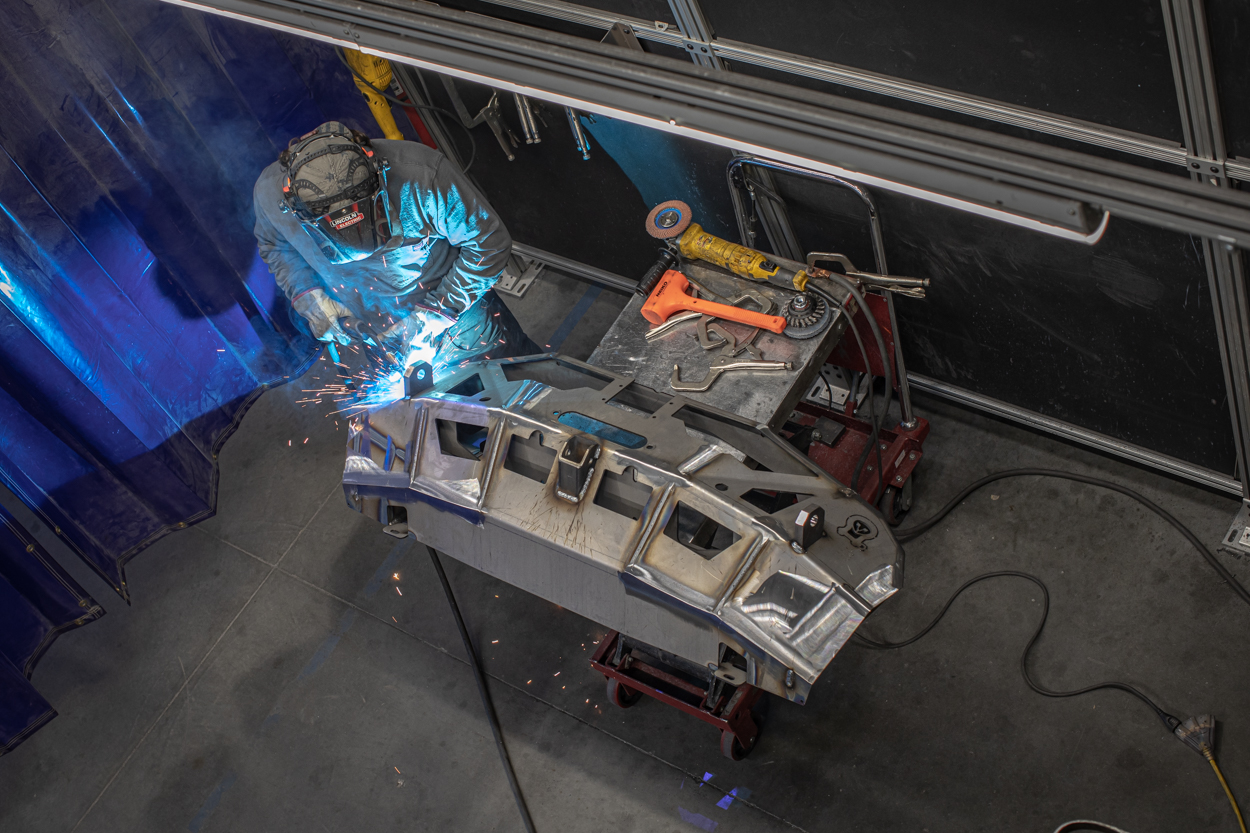

People & Process

Moving beyond robots, people still play a (large) majority role. There are several machines, that while very capable, still need to be guided by expert hands. As we toured the facility, we saw a multitude of complicate machinery. Most of them, I wouldn’t even know where to start.

The whole routine they have is very carefully calculated. In order to scale to managing a bunch of people (and robots), you need to be able to manage the process well. After watching everyone work for about two hours, every single thing felt right. Like it was all in the right place.

Lead Times

The goal of every fabrication business is to get products out fast. Fabrication is a long and tedious process and it’s a long road to getting to a point where you can provide products on the shelf for eager customers.

Backwoods has done exactly that. A big chunk of their building is dedicated to stocking, shipping and fulfillment. There are shelves of ready to go ship items (even big items like bumper systems). You don’t have to waits months for a bumper, they’re ready today!

Brand Vehicles

Backwoods actively does all their own product development. That means they often have all the vehicles on hand, and a few specifically built for shows and trail riding. You can see their 3rd Gen Tacoma, followed by a 3rd Gen Tundra. 3rd Gen Tundra products are in the works, and they should be cranked out and ready relatively soon.

They’re also closely related to Chandler Truck Accessories. You can see a GMC truck way in the back. While they don’t build Tacoma products, they do build more trade and work oriented storage systems for full sized truck. That does include the Tundra.

Real World Testing

I’ve watched the team, and others, test these products for quite a while. They’re not gentle with their trucks. I say this is a good way… Don’t come after us Backwoods leadership… haha.

But seriously, the products are thoroughly developed, testing and improved. From the few days I spent with the team, both on and off-road, I could tell that they were enthusiasts at the core, and that’s great to know.

My Truck

I figured this would be a perfect place to share this picture. My dad was driving on the way to camping at a local OHV park.

Anyway, I run Backwoods on my personal truck. Front and rear bumper. I love the look of the front bumper, the front end is super sleek compared to my previous setup. Nothing against the old truck, but V2 just hits different. The rear is great too, I just wish they still made the swing out! This is your indicator to bombard them with interest until they make one again…

Final Thoughts

If you’re lookin for a good company to support, I don’t think you can go wrong with Backwoods Adventure Mods. We were pretty impressed, from the moment we walked in, to the moment we left. And a friend of mine who tagged along works in the world of machinery. Collectively, we had a good experience pool to base our judgement off of.

Stoked to see new brands driving hard to innovate and provide us with new options. Thanks to the team for showing us around!

Extra Photos