Ford on Friday confirmed the project name for its next-generation electric truck: Project T3.

Short for “Trust The Truck,” the project aims to create a truck that’s “fully updatable, constantly improving, and supports towing, hauling, exportable power and endless new innovations owners will want,” according to a press release from the automaker.

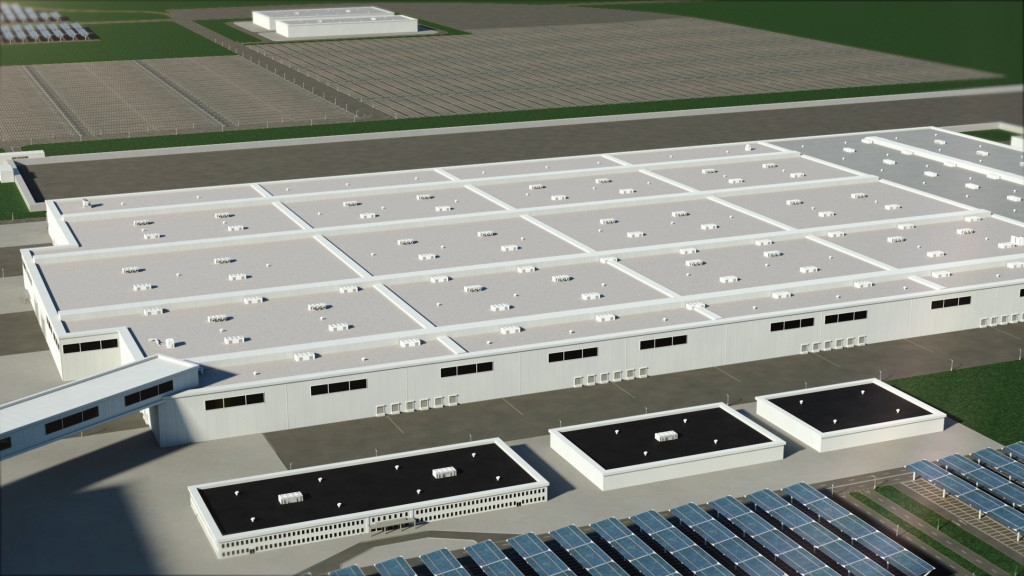

The announcement comes just before an event scheduled Friday to preview the company’s mammoth BlueOval City plant in Tennessee, which Ford says will be capable of producing 500,000 electric trucks a year at its peak rate.

That’s several times the accelerated 150,000-per-year rate at which Ford plans to make the F-150 Lightning, and next-generation EVs from this plant will be a significant portion of the 2 million EVs per year Ford intends to make globally by late 2026.

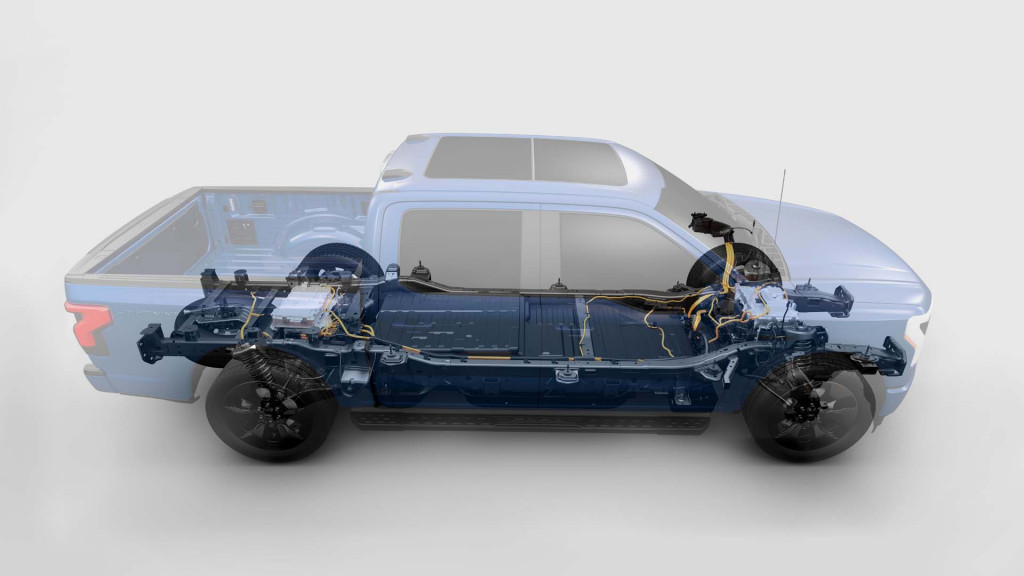

2022 Ford F-150 Lightning pre-production

Ford has confirmed that multiple products will be produced at the BlueOval City plant, including from the Lincoln luxury brand. The project, and accompanying vision, may have been underway by late 2021 amid very strong interest in the F-150 Lightning electric pickup, even before it had been delivered. Then, Ford confirmed that the next-generation truck would be built on a dedicated EV platform and be made in “incredibly high volume.”

The company offered no further details regarding the upcoming electric truck itself prior to the plant event, although a statement included in the release from CEO Jim Farley added some color.

“PJ O’Rourke once described American pickups as ‘a back porch with an engine attached,” said Farley in an accompanying release. “Well, this new truck is going to be like the Millennium Falcon—with a back porch attached.”

Farley further said that the truck will be the product of a breakthrough manufacturing process with “radical simplicity, cost efficiency and quality technology.”

2022 Ford F-150 Lightning

That goes right along with what Farley said in February. Then, he also said future Ford EVs will be “radically simplified” with fewer body styles, a limited number of build combinations, and a reduction in weight and complexity—to do more with the smallest battery pack possible.

The company noted that BlueOval City is a key part of being able to scale up EV production, making them more accessible to customers. Farley has said that an EV price war could make the market extremely competitive—something that may have been unfolding in the market in recent months with Tesla’s across-the-board price cuts and ensuing Mach-E price reductions, for instance.

Ford Blue Oval City – rendering of manufacturing complex in Tennessee, September 2021

Ford Blue Oval City – rendering of manufacturing complex in Tennessee, September 2021

Ford Blue Oval City – rendering of manufacturing complex in Tennessee, September 2021

Vertical integration is built into the plant. Ford boasted that battery making will be closely aligned with production and the battery supplier, SK On—to the extent that battery cells will be made, put into packs, and delivered in less than 30 minutes to the assembly plant.

It will also have its own upfit center where bedliners, toolboxes, and the like can be installed robotically.

The automaker together with SK On are investing $5.6 billion in the campus, and it will create about 6,000 new jobs. It will be the company’s first carbon-neutral manufacturing and battery campus. In the case of the new Tennessee facility, it’s using recovered heat from the utility infrastructure plus a geothermal system. The company seeks to power all of its plants with “renewable and carbon-free” electricity by 2035.