Ask futurists which materials have the potential to make our lives better in all sorts of ways, and odds are the resulting shortlist will include graphene.

Graphene has become a bit of a buzzword for startups in a range of areas, and it takes center stage in Lyten’s lithium-sulfur EV batteries.

A 300-million-euro ($320 million) investment from Stellantis Ventures announced Thursday will enable Stellantis and Lyten to develop solutions together with these batteries plus additional technology from the California startup.

It’s claiming some serious supply-chain advantages and environmental bona fides, too. The companies say the Lyten battery has “a pathway to achieve the lowest emissions EV battery on the global market.”

Stellantis and Lyten – 3D graphene

Lyten is currently quoting a 6% lower carbon footprint in the manufacture of the battery compared to NMC batteries, and it’s working on a plan to lower that towards carbon neutral, according to Keith Norman, Lyten’s chief sustainability officer.

Lithium-sulfur cells have long been seen as a chemistry with strong potential but with real-world barriers around cycle life, or degradation, as well as manufacturability. Going back to earlier last decade, experts have been seeing lithium-sulfur battery tech as becoming commercially viable around 2030, and if all goes well Lyten’s tech may be on the leading edge of that.

Looking back, Australian researchers in 2020 reported that they saw the potential to double EV range with lithium-sulfur cells, but they faced issues with a low cycle life. Other researchers successfully introduced a manganese nanosheet composite to control this undesirable “shuttling” behavior, but that poses manufacturing issues. Researchers at the DOE’s Lawrence Berkeley National Laboratory overcame the issue with “a sulfur-graphene oxide nanocomposite cathode,” but manufacturability there too appeared to get in the way.

Lyten illustrating 3D graphene

Why lithium-sulfur might work this time

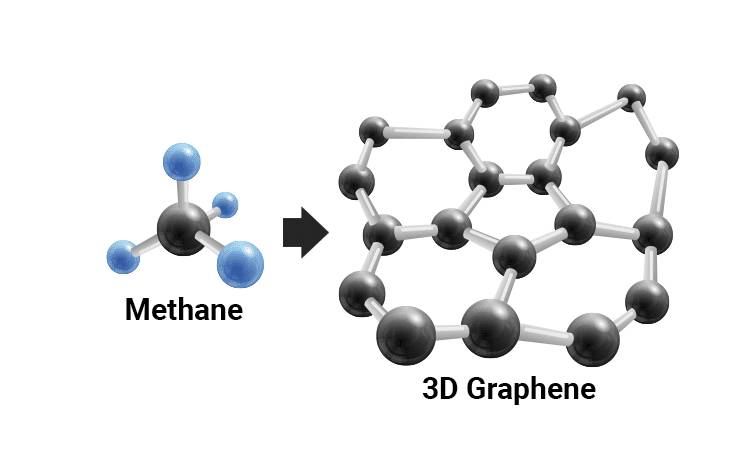

Lyten claims to be “the pioneer of tunable 3D graphene supermaterials,” and the firm says that it’s what makes the lithium-sulfur battery chemistry possible.

For the lithium-ion battery, the graphene helps hold sulfur atoms in place and prevent that shuttling of them as it charges and discharges. Secondly, it helps allow greater energy density, simply through the 3D texture.

To get graphene from a planar sheet of carbon atoms to something useful here, it uses a “patent-protected reactor technology” to convert that planar structure to “three-dimentional carbon shapes and structures”—essentially taking a piece of paper and crumpling it. That, according to Norman, brings the reactivity up by orders of magnitude, and allows the company to tune the materials to the characteristics it needs.

Lyten claims that its chemistry brings a 60% lower carbon footprint versus today’s lithium-ion cells. The company says that it can deliver more than twice the energy density of lithium-ion cells,

The company also says that it can produce its 3D graphene n a carbon-negative manner at scale while, with all the rest of the battery in consideration it can deliver “a world-leading carbon footprint.”

STLA Large platform – Stellantis EVs

EV battery tech that can go global

It also says the tech is good to take global—partly because of its simplified bill of materials.

As exotic as 3D graphene sounds, these lithium-sulfur batteries need no nickel, cobalt, or manganese for their cathodes, and that takes a huge burden off automakers and battery makers in metal and mineral procurement.

Lyten makes the graphene from natural gas (methane), in a process that they say can be carbon negative (as it produces hydrogen as a byproduct). That natural gas is abundantly available. So is sulfur, as a waste product of the mining industry. That helps simplify the supply chain and eliminate some of the geopolitical risk. Meanwhile, lithium investment is quite dispersed around the globe, the firm says.

Because of those lower costs, Lyten believes it has “a battery chemistry for the masses,” as Norman put it—especially when you consider that, capacity the same, it can reduce EV weight.

Cylindrical, pouch, and prismatic cell formats

Cylindrical cells – Lyten

Lyten pouch cell

Lyten prismatic cell

Lyten is also looking into a wide range of form factors already made by big battery players like Panasonic or Samsung SDI, leading with cylindrical cells in a common 18650 format, then including pouch cells and eventually perhaps prismatic. Thus, they’ll be able to be fitted into all sorts of applications—including potentially aerospace and last-mile delivery.

Further, it can be made on the same equipment as existing nickel-based cell lines, the firm says.

Wouldn’t require new EV battery factories

“We’ve been able to develop our lithium-sulfur solution to basically be producible on existing types of manufacturing technology lines, with some very modest modifications,” said CEO and co-founder Dan Cook. “We estimate somewhere in the neighborhood of about 10 to 15% of the direct costs of the manufacturing line itself to make minor modifications to handle the lithium-sulfur architecture.”

Lyten has just opened a pilot lithium-sulfur battery line in San Jose and will be delivering batteries to customers for testing and qualification soon. The goal of that line is to produce about 200,000 cells a year and test the equipment and production process, but it hopes to establish a gigawatt-scale line to speed up EV adoption in the second half of the decade.

Cook said that the company is looking to deploy its tech in the U.S. initially, then Europe and beyond as the company progresses.

Besides batteries, Lyten is also working with Stellantis on a new generation of sensors, and on using its graphene to make lightweight composites that could help reduce the weight of vehicles.

The investment in Lyten is altogether part of Stallantis’ Dare Forward 2030 strategic plan and its aim to cut CO2 in half by 2030, and be net-zero by 2038. Series A round was $160 million, while Stellantis is a significant part of its Series C round.

Stellantis targets net-zero carbon emissions by 2038

Production later in the 2020s?

Stellantis is looking at the second half of the decade to incorporate the batteries into its EV platforms.

Lyten says that it’s already achieving densities equal to and above lithium-ion, but on cycle life it’s still a work in progress, on a quarterly basis, with Stellantis and the companies agreeing that’s where the work needs to be done. With U.S. and EU regulators likely to step in this decade on battery degradation and cycle life, there has to be a solution before the tech is commercialized.

Is this a future popular battery tech for EVs? There’s no knowing without pushing it farther along toward manufacturing, and it might have the potential to leapfrog lithium-ion as we know it.