We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

With nearly 20 years of active infantry service and accredited by General George S. Patton as “the greatest battle implement ever devised,” the M1 Garand is one of the most notable service rifles in history. It’s a rifle that was revolutionary, effective, and for many decades, common. It’s a rifle that two generations were raised on—those that served with it, and their kids. The rifle is an icon that’s widely recognized, even idolized. But these days, anything beyond surface-level knowledge and experience with the M1 Garand is becoming rare.

The M1 Garand is seen by many as an embodiment of the greatest generation and their defeat of Axis powers. It’s hard for me to pick one up without imagining what it must have been like for my grandpa to press his cheek against the stock and gaze through the peep at the front sight, pointing into the frozen Ardenne. To me, it’s also a symbol of old school marksmanship, a tight 1907 leather sling, and pulling targets in the pits.

I competed in service rifle competitions for a number of years and shot several M1 Garand novelty matches, but I never owned my own Garand. I started out competing with the M1A, a derivative of the M1. Like many other shooters, I had a basic appreciation of how the M1 Garand works, but not much else. Many years overdue, I finally bought my own M1 Garand to learn, shoot, and enjoy.

A Brief History of the M1 Garand

There are many published histories of the M1 Garand rifle, most of which are regurgitated ten times over. A more detailed history of the rifle is published by the Garand Collector’s Association, but I’ll give you the Cliffnotes version.

The M1 Garand was designed by John C. Garand and accepted by the Army in 1936. It was originally intended to hold 10 rounds and chambered in .276 Pedersen, which is a medium-sized 7mm cartridge that fired a 125-grain bullet at 2750 feet per second. For various reasons, the Army wanted it in the already standard-issue .30/06 Springfield.

The M1 Garand went on to serve through World War II, Korea, and the phase-out started in 1959 when its derivative, the M14 chambered in 7.62x51mm began replacing it. Garand designed the rifle while working for the U.S. government at Springfield Armory and gave them his patent rights to his creation. Ironically, in the March, 1974 issue of the NRA’s American Rifleman, that went to print within a month of Garand’s passing, there’s an editorial describing the efforts of Congress to award the aging inventor of the M1 $100,000. He’d only ever gotten his standard pension, and according to the editorial, the Department of the Army said, “Not another cent.”

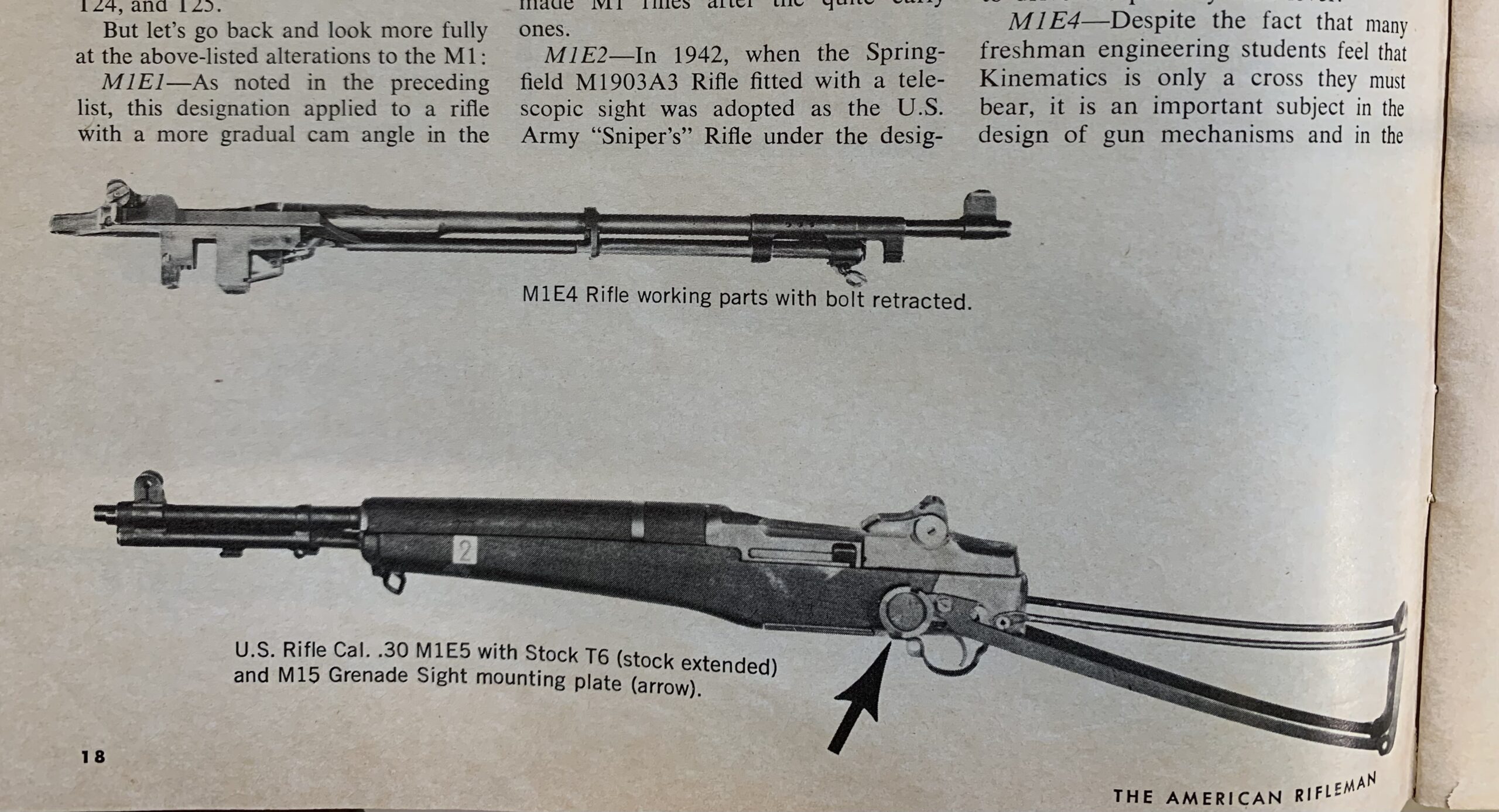

There were several iterations of the M1 Garand, but none as widespread as the standard-issue infantryman’s rifle. The M1C and M1D were specialized scoped variants. Additionally, there was an entire M1E series which is detailed in that same March, 1974, issue of American Rifleman. Those ranged from M1E1 through M1E9 and led to the development of the M14 and its single-fire counterpart the M1A. Additionally, Beretta produced a box-fed, select-fire version, the BM-59. The Ruger Mini 14 is still in production, and is based upon the design of the M14 and consequently, the M1..

The M1 Garand is Rapidly Becoming a Mystery

I felt like a kid unwrapping his first .22 when I finally got my M1 Garand. It was beautiful. I bought an M1 that had been purchased from the Civilian Marksmanship Program (CMP) as a “special grade” rifle. What that means is that although it has an original 1944 receiver, my rifle has been completely refinished, refurbished, and fitted with a brand new barrel and wood furniture. My rifle isn’t something a collector would go silly over, but I want a quality functional example to shoot. My heart dropped when the rifle wouldn’t cycle correctly. It would eject empty cases, but the bolt wasn’t coming far enough back to strip the next round from the magazine.

Who Knows the M1 Garand Anymore?

Where does someone even take their sick M1 Garand? That question is much harder to answer today than it was 40 or 50 years ago. Fortunately, I’ve got a guy. Ken Corcoran was a shooter and gunsmith with the Army Marksmanship Unit, and a distinguished rifleman. Although he worked primarily on M1A’s, M16’s, and AR-15’s, he built and worked on hundreds of M1 Garand rifles too.

I received a thorough and salty education from Ken when I first met him at 19 years old, and I still learn something every time I visit with him. Back in about 2005, I brought him my recently purchased Springfield M1A—I wanted to become a service rifle shooter. He was a key mentor to me in that endeavor. He’d take the time to explain everything from how light conditions change my point of impact on the target to why I should dab grease between the stock ferrule and op rod guide of my M1A. His knowledge of the M1 Garand is equally humbling.

Nearly 20 years later, I was bringing him another rifle. With approximately two minutes of investigation, he diagnosed the cycling problem to be a result of an undersized gas port in the aftermarket barrel and an aftermarket gas cylinder lock screw that increased the volume of the cylinder itself. He drilled out the gas port, installed a G.I. gas cylinder lock screw (gas plug), and the rifle ran perfectly.

If I hadn’t had access to someone with the experience-based knowledge, tooling, and parts to fix the issue, I’d have had to send the thing off to who knows where. The M1 Garand isn’t an enigma, but it’s a craftsman’s rifle that requires the parts and the know-how to diagnose and solve problems. Both will only dwindle as we trek into the future.

How Does the M1 Garand Work?

In the world of gun culture 4.0, Youtube, and larping, everyone recognizes the M1 Garand. They know it’s chambered in .30/06, loaded with 8-round en bloc stamped steel clips. If they have even the slightest familiarity with the M1, they know that when the last round is expended, those clips sound off with a beautiful ping as they’re ejected from the receiver. To most, what’s actually happening under those battered wood hand guards and stock is a mystery. Here are the basics of how the M1 Garand works. To follow along, or learn more on M1 Garand nomenclature, the CMP has an excellent guide.

The M1 Garand Ping: Magazine and En Bloc Clip

The best known feature of the M1 Garand is its use of an 8-round clip rather than a detachable magazine or stripper clip. The fully-loaded clip is pressed down into the magazine until the magazine follower is pushed far enough to unhook the operating rod catch and simultaneously capture the clip with the clip latch. When the clip clicks into place, the shooter rapidly withdraws their hand and the bolt slams forward, stripping the top round off the clip and into the chamber. Once you stop applying pressure on the clip, the bolt leaps forward. If you don’t get your thumb out of the way, you’ll quickly find out what “M1 thumb,” or “Garand thumb” is all about.

The clip is the same on top and bottom, and can be installed either way. The edges of the clip act just like feed lips in a modern rifle magazine. As each shot is fired, the follower presses the stack of cartridges up through the clip. When the last round is fired and ejected, the op rod catch simultaneously locks the operating rod open and pulls the clip latch from the small notch in the steel clip. When that happens, the clip ejector spring located in the trigger assembly sends the empty clip flying into the air with that characteristic ping, signaling the shooter that they’re out of ammo.

Long Stroke Gas Piston

Another key characteristic of the M1 Garand is that it operates on a long stroke gas piston system, and was the greatest early success of the concept. It’s alleged that the design for the AK-47’s gas system was borrowed directly from the M1 Garand—albeit flipped upside down. Unlike Soviet rifles such as the SKS that used a short piston which knocked the bolt carrier group backward, the M1 Garand and AK-47 both implement a gas piston/operating rod that directly operates the bolt.

At the front, the operating rod starts with a precisely machined piston. It’s seated at the end of a hollow steel tube. The operating spring—it does much more than just absorb recoil—fits inside this hollow tube and slips over the follower rod. The op rod then transitions to a flat bar with a charging handle and bolt lug guide at the end. With the action closed, it extends from the gas port just behind the muzzle, to the bolt lugs just behind the chamber.

Upon firing, in the short time that the bullet is between the gas port and the muzzle, hot gas rushes through the gas port, driving the piston back, which in turn rotates the bolt out of its locked position, and draws it to the rear, ejecting the spent case. The operating spring then drives the op rod forward, chambering a new cartridge, rotating the bolt lugs into their locking recesses, and finishing with the piston back in its original position.

The M1 Garand Runs on Levers, Linkages, and Timing

A fascinating thing about the M1 Garand and its function is that everything outside the trigger group is driven by the operating spring. The spring absorbs recoil and returns the rifle to battery after firing, but it’s also used to drive the magazine follower and actuate the operating rod catch, and clip latch. In most modern CNC-made firearms, we see a separate magazine spring under the follower, but this 1936-vintage design is actually more complex. A few seemingly simple parts work in unison to make this incredible rifle work.

According to Corcoran, timing issues can be common in this system of linkages. However they aren’t always easy to diagnose to the untrained eye. In the era where the M1 Garand was king, one would simply throw in a timing block, replace a couple small parts, and be back in business. Firearms News has a pretty informative article on checking the timing on an M1 Garand, and according to Corcoran, problems like your rifle ejecting clip along with the last round or two, or trouble getting the bolt to release when loading a clip can be indicative of timing issues—though he wouldn’t venture to diagnose a rifle without getting his hands on it.

Buying an M1 Garand

The “good ol’ days” of plentiful M1 Garands are long gone but, with a little direction, you can still get your own functional piece of history. If you’re wanting a matching-parts, collector-grade rifle, you’ll be entertaining an entirely different set of questions and price range than if you simply want an M1 Garand to shoot and enjoy. Either way, it helps knowing where to look and what to look for.

Where to Shop for an M1 Garand

If you’re “chasing the Garand” as my friend, expert long-range shooter, and OL contributor Sean Murphy puts it, organizations like the previously mentioned Garand Collector’s Association and CMP are great sources of information on what to look for and where to look. Collectible M1 Garands aren’t getting any more common—or less expensive.

For the average shooter, the CMP is probably still the most reliable source for acquiring an M1 Garand. Although quantities are more limited than they used to be, and there are a couple qualifiers that you have to meet, you can order a rack grade M1 Garand from the CMP for about $750 through the mail. The CMP website goes into detail about the requirements and specifics about what you’re getting with each grade of rifle.

If you know what to look for, don’t want to wait on a mail-order rifle, and are willing to take a little risk, M1 Garand rifles are often available on sites like guns.com and Gunbroker. That’s where I bought mine, and they do offer some purchase protection. Understand though, that none of these rifles are new.

What to Look Out For in an M1 Garand

Depending on where you’re at, you might be able to find an M1 Garand in the used rack of your local gun shop. This can be a good way to buy one, but there are a few things you should check if you can. Guys like Corcoran could give a post-grad lecture on things to look for or avoid on a used Garand. In fact, when I visited him, I had another M1 in tow. He took one look at it and said, “oh, that’s a Danish rifle.” When I asked how he knew that, he simply replied, “I looked at it.”

You and I don’t possess such knowledge, but there are few things we can inspect when shopping for one in person:

- Price: Any retail-sold, shootable M1 is going to cost at least $1,000. Double that for a really good one.

- Corrosion: If you’re allowed, field strip the rifle and inspect all parts for pitting or excessive rust that can’t be wiped away with some oil.

- Tip Test: with the operating spring removed, the op rod and bolt should slide freely to the rear when the muzzle is pointed up at approximately 60 degrees. They should close when pointed down approximately 60 degrees. Here’s a video demonstrating it. The gist of this test is to ensure that the op rod moves freely back and forth and isn’t bent or damaged.

- Check the stock and inside of the front hand guard, as well as the edges of the gas cylinder for signs that the op rod is wearing on them.

- Inspect the bore with a flashlight for excessive rust—with the rifle stripped and bolt removed.

- If you see something that doesn’t feel right, it’s probably not.

Some of these indicators aren’t necessarily big problems, but they can be red flags. Take your time and research markings, manufacturers, and corresponding dates. I recently saw an M1 Garand for sale in a shop that was marked as “correct grade” with a price tag of $1750. The 500,000-series serial number indicates an early vintage rifle, but without the research or know-how, it’s damn tough to tell exactly what you’ve got. Most Garands have been refurbished and rebuilt with a mix of parts—usually more than once. Thick patches of rust that were clearly visible inside the end of the bore were a red flag.

Shooting and Maintaining an M1 Garand

The M1 Garand is fun to shoot, but recoil is much heftier than the contemporary AR-15 service rifle. Some view this as a negative, but plenty of old school service rifle shooters are quick to point out that shooting one in competition forces you to build good positions. If you don’t, it’ll knock the piss out of you. The steel buttplate on the old warhorse can wear on your shoulder when shooting from the bench, but recoil is softer than that of an average bolt-action .30/06 hunting rifle. They have a two-stage trigger that usually breaks between 4.5 and 6 pounds.

Proper Lubrication of the M1 Garand

The M1 Garand is made from hand-machined steel parts, and its relatively complex function requires that you lubricate it properly. If you don’t, you’re going to have problems. You might even damage your rifle. When completely degreased, my rifle’s bolt can’t even be drawn to the rear without binding. Gun oil is helpful for some parts of the M1 Garand, but what you really need is grease.

The previously mentioned story on the evolution of the M1 Garand stated that in development, sustained fire using normal oils and lubricants would dry the guns out and actions would seize—particularly in wet conditions. Lubriplate 130-A was adopted as the standard-issue grease for the M1 Garand, and you can still buy it today.

GAA, or Grease, Automotive and Artillery is what Corcoran recommends. This old army staple is an excellent lubricant for the M1 rifle, and it’s what I used for my M1A match rifle many years ago. It’s cheap, or was, and cleans off easily. It’s not in every army surplus store these days, but you can still find it. Other greases like Shooter’s Choice Gun Grease work well too.

It’s key to apply grease to several areas on your M1 Garand. The bolt and op rod channels and locking recesses in the receiver should be given a thin coating. Grease should be applied to other areas of contact, or where wear is visible on the bolt, inside the bolt lug recess on the operating rod, and on the bottom of the barrel where the operating rod should have light contact with the chamber. Brownells has an excellent video detailing this procedure.

M1 Garand Ammo: Do’s and Dont’s

It’s commonly stressed that you should not shoot standard factory .30/06 hunting ammo through your M1 Garand. The rifle was designed to operate within a certain range of gas cylinder pressures and common advice tells us to use ammunition at or under 50,000 PSI. M2 Ball ammunition was the standard feed for the M1 Garand. It fires a 150-grain FMJ bullet at approximately 2,750 feet per second. You’ll often hear that you shouldn’t shoot bullets heavier than 150 grains, but national match ammunition for the Garand, of 1965 vintage, fired a 174-grain bullet at 2,663 feet per second. Some loads with heavier bullets, particularly those using modern slower-burning propellants, can overpressure the gas cylinder and bend or otherwise damage the operating rod. Just how legitimate is the concern?

“These guys have no idea what we used to do with Garands. We’d load 190-grain bullets for shooting at 600 yards all the time,” said John Karish, who is the other of my two main service rifle mentors. Karish grew up in California, when shooting NRA high power matches with M1 Garands was as regular as sunshine. When I asked Corcoran how easy it was, really, to bend an M1 operating rod, he said nothing. He walked over and reached behind a piece of equipment in his shop, pulling out a World War II vintage op rod. He brought it over to his bench, set it across two wooden blocks, picked up a mallet, and gave it a dramatic and swift overhand strike, right in the middle. Ken then handed it to me and said, “How hard do you think? Does that look bent to you?”

Despite the demonstration that showed me that these rifles might not be as fragile as everyone says, we aren’t living in a time when everyone has an M1 Garand gunsmith right down the road—or an excess of operating rods or parts. There’s no need to shoot high pressure ammo, so just use caution. Many manufacturers including Winchester, Hornady, Federal, and Fiocchi load specific M1 Garand ammo, and safe load data is readily available. Simply grabbing the first cheap .30/06 ammo you find can beat your rifle up and accelerate wear and tear at best, or break it at worst.

If you really feel the need to fire heavy or high-pressure loads, you can get a Schuster gas plug that is adjustable to vent excess gas and safely fire heavy-duty .30/06 ammunition. Another aftermarket part, “that bullshit gas plug” that my rifle came with, is hollowed out to create more space in the gas cylinder and reduce peak pressures. Some folks seem to have good results with it, but my rifle will not cycle with standard ammunition. Whatever you choose to do, use caution.

How Accurate is an M1 Garand?

Despite casual claims that the average M1 Garand is a superbly accurate rifle, it’s nothing special in standard-issue configuration. It won’t win benchrest competitions, but it’s accurate by infantryman’s standards in the hands of a good shooter. One of my favorite M1 Garand stories is when one day, about 20 years ago, Karish outshot the entire 1st battalion of the 501st Parachute Infantry Regiment on the army’s pop-up qualification range at Fort Wainwright with his Garand. His only complaint was that he’d drawn a pesky double target in the middle of a reload.

Reasonable Expectations for the “As-Issued” M1 Garand

We live in a world when terms like “minute-of-angle” are thrown around lightly, and some attribute this kind of accuracy to their Garands. The right match-grade M1 Garands with the appropriate spells cast upon them, fired by skilled shooters can do such things, but you shouldn’t expect it out of your rack grade or as-issued rifle. If you can maintain 3- to 4-inch groups at 100 yards with iron sights and ball ammo, you’re doing well.

I took my M1 to an unofficial mid-range prone match, which was fired from 600 yards on standard NRA high power targets. Shooting Hornady’s M1 Garand Match ammo, I was able to keep 16 of 20 shots inside the 36-inch black bullseye. Not great shooting, but about what I expected from that rifle in my first match in 14 years. For reference, I was able to keep more than half my shots in the 6-inch X-ring when shooting a 16-inch AR-15 carbine that I used in my recent 5.56 ammo test. It had a 10x LPVO scope and a bipod. At the peak of my service rifle shooting, I averaged around 195 with my national match AR-15 using iron sights. That’s keeping about 15 of 20 shots inside the 12-inch 10-ring. Shooting accurately with as-issued iron sights on an M1 Garand is much more difficult than the average trigger puller realizes.

The Accurized M1 Garand

“The M1 is a craftsman’s rifle. It takes a craftsman to make it shoot well and keep it shooting well. The AR-15 is a machinists rifle, and just about anyone can assemble an accurate one with the right parts.”

Karish told me that many years ago, and he was right. I can simply order the right parts and assemble a very accurate AR-type rifle, or bolt-action for that matter. Getting the M1 Garand to shoot well enough to compete and replace bolt-action service rifles was no easy task. A lot of work was done in the 1950s to develop the National Match M1 Garand, and the techniques used to accurize the platform.

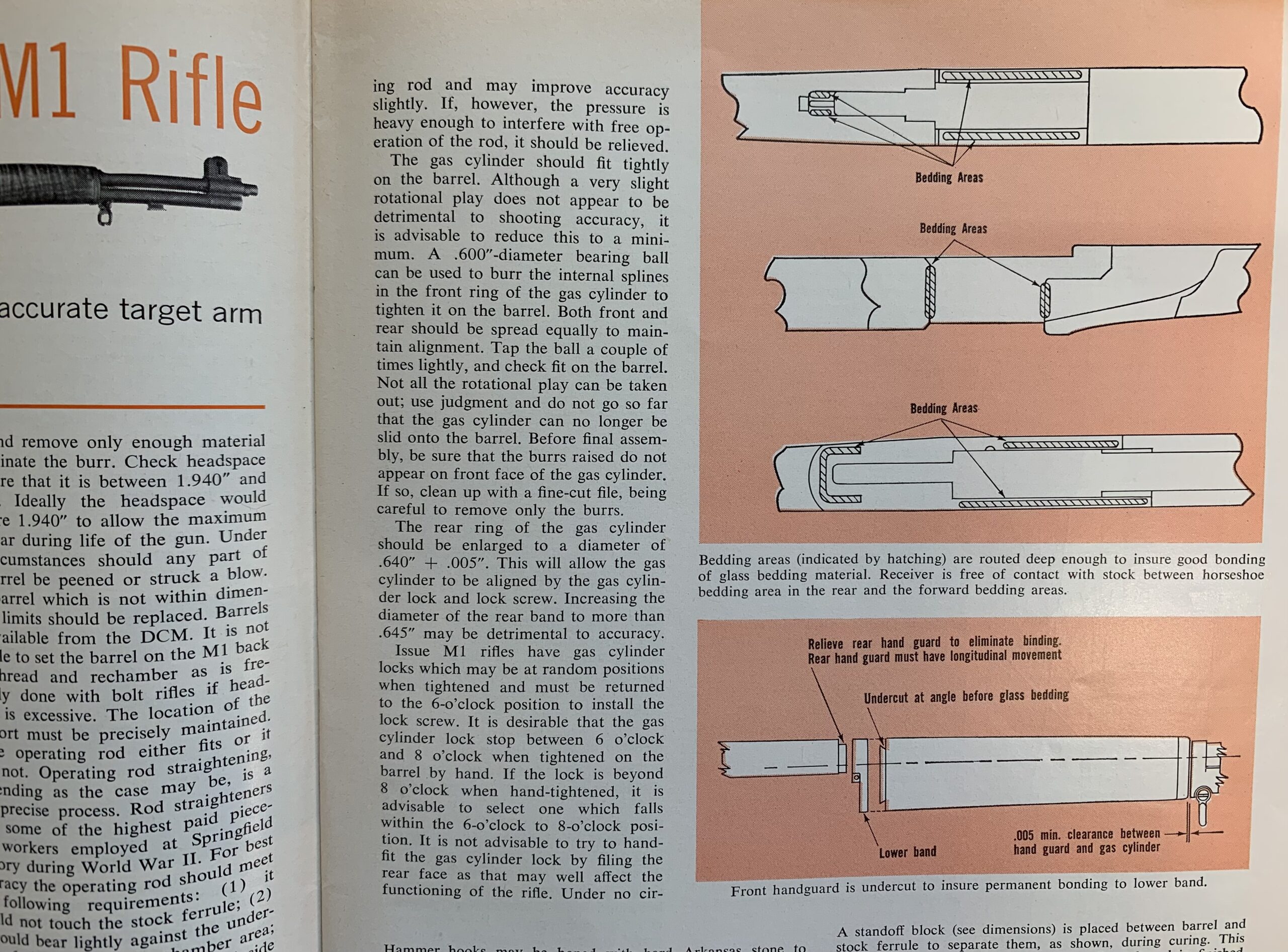

An article by Capt. Carl J. Davis in the July, 1965 issue of American Rifleman details this in-depth process. In all, it describes the following 13 significant alterations and specifications in an illustrated diagram:

- A. Service rifle front and rear sights replaced with National Match sights. No perceptible play between aperture assembly and sight base at 40 clicks elevation

- B. Headspace between 1.940 inches and 1.950 inches

- C. With operating rod spring and follower rod removed, bolt opens fully by its own weight when muzzle is elevated to approximately 60 degrees. With Muzzle depressed to approximately 60 degrees, bolt closes fully by its own weight

- D. Muzzle crown free of all burrs and nicks

- E. Clearance of .010 inches between stock and receiver at point indicated, stock glass bedded.

- F. Operating rod handle may bear lightly on stock. The tube does not contact stock, gas cylinder, or stock ferrule. Operating rod bears lightly against underside of barrel in chamber area

- G. Rear handguard does not contact operating rod

- H. Rear handguard has longitudinal play

- I. Rear handguard does not contact stock

- J. Stock ferrule free of contact with lower portion of lower band, leaving approximately 1/64-inch clearance

- K. Front handguard has no longitudinal movement

- L. Minimum of .005 inches of clearance between front handguard and gas cylinder

- M. No rotational movement of gas cylinder. Gas cylinder lock should stop between 6-o’clock and 8-o’clock positions when hand tightened

Sounds simple, right? This was a strenuous and detailed-oriented endeavor that surely took a lot of repetition to master. It’s no wonder that the match-grade AR-15 overtook the old M1 and M1A as soon as quality float tubes and high-BC projectiles were developed for it.

The M1 Garand in Competition

The M1 Garand was the standard for NRA and CMP service rifle competition from the late 1950’s through the mid-1960’s, and remained a strong competitor for many more years. Serious competitors have long-since switched to shooting the AR-15, and now low-magnification optics are even allowed. The competitors bringing match-grade M1’s to the line these days are doing it for pure enjoyment of the sport.

Vintage “As-Issued” Rifle Matches

Vintage rifle matches have seen a surge in popularity, and each year at Camp Perry, the CMP hosts a variety of them. Many rifle clubs host these “as-issued” matches around the country too, and they are some of the funnest matches you can shoot. Among the rules, an M1 Garand must be an “as-issued” rifle. There are a number of specific rules, but essentially, the glass-bedded, national match rifles with improved sights can’t be used. The course of fire can vary from match to match, but they’re commonly shot at 200 yards, or 100 yards on a reduced-size SR1 target face. This is the standard NRA high power target for the standing and sitting or kneeling positions. In a normal Garand match, you’ll fire three ten-round strings: one prone slow fire, one prone rapid fire, and one standing, for a total of 30 rounds.

M1 Garand FAQs

What caliber was the M1 Garand?

The M1 Garand was originally developed for the .276 Pedersen cartridge, but adopted by the U.S. government in .30/06 Springfield.

What made the M1 Garand so good?

The M1 Garand offered higher capacity and a faster rate of fire than other infantry rifles of the time. It was also utterly reliable.

What was the M1 Garand replaced with?

The M1 Garand was replaced with the similar but more optimized M14 beginning in 1959.

How much should I pay for an M1 Garand?

You can get a “get what you get” rack grade M1 Garand from the CMP for around $750. From a retailer or private party, expect to pay $1,000 for a rifle that is in working condition, and over $1,500 or $2,000 for a nice one.

The Future of the M1 Garand

I’d like to say that the future for the M1 Garand looks bright, but eventually they’ll all be gone. So will anyone who was ever issued one. Done are the days where M1 rifles and parts were cheap and plentiful, but that’s life. The good news is that you can still get an M1 Garand and shoot the hell out of it.

We now live in an era of Youtube, social media, and instant gratification. For all our CNC-machined precision, we’ve lost a level of earned experience and craftsmanship that can only be obtained by bedding a dozen rifles before lunch, then shooting across the course. The M1 Garand represents a different era that can mean different things to different people, but tapping into it for a brief moment is only a ping away.