BMW M70 V12 Engine: A History of Innovation and Performance

In days gone by, some engineers in a large shed in Coventry, also known as Jaguar Cars, built what was considered the best production engine in the world – their 5.3 liter V12. Mercedes attempted to surpass it but failed. Meanwhile, BMW explored different options, such as combining two M20 sixes on a common crankshaft, but they realized they needed to think further ahead.

How BMW Beat Mercedes-Benz to the Punch with its First V12 Engine

During the early eighties, while developing the M70, BMW recognized that the SOHC M20 was becoming outdated and in the process of being replaced by a 24-valve M50 successor. Not only that, but they were also working on an all-new M40 four-cylinder OHC unit to replace the M10 that had been in production since 1962, which includes models like the 2002 and Neue Klasse.

The M40 engine boasted several advantages: it was smaller, lighter, quieter, more powerful, and more fuel-efficient, thanks to its clever piston crown and combustion chamber design. Additionally, it utilized finger rockers and hydraulic tappets. Most importantly, it was designed for mass production. On the other hand, the V12 engine was always meant to be more of a vanity project than a best-seller. Consequently, the M70 V12 was based on the M40 design and manufactured using the same tooling. Yes, vanity played a role. BMW aimed to outpace Mercedes-Benz and construct the first German V12 luxury car, and they achieved this feat four years ahead of their competition.

The M70 V12 Engine: A Smooth, Reliable Powerhouse

However, as the E32 750iL was being introduced in late 1987, BMW was already developing a new generation of all-alloy V8 32-valve engines to replace the old M30 sixes. Thus, the M70 was designed as a relatively low-cost project that heavily relied on high-volume production parts, many of which were derived from the M40 itself. These included connecting rods, rocker arms, and valves. Although the pistons shared a similar design, they were made from a different alloy and featured slightly offset gudgeon pins, resulting in asymmetrical pistons.

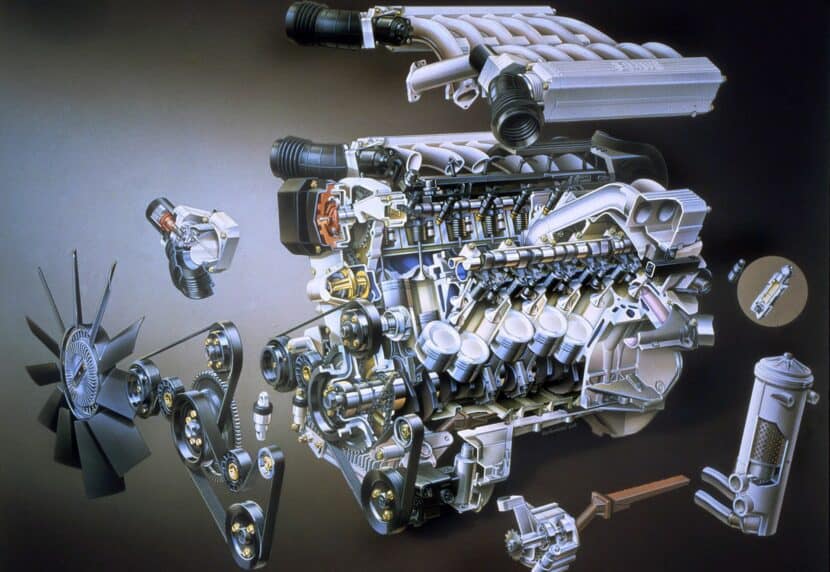

The M70 utilized an alloy block cast in Alusil silicon alloy, which involved boring, honing, and finishing the cylinders without steel sleeves. During the finishing honing process, tiny silicon crystals were revealed, providing a surface on which the special pistons and rings could run. The long steel crankshaft was counterweighted, and each bank’s overhead camshaft was driven by a simplex roller chain connected to the crankshaft, with a second chain driving the oil pump.

Rocker fingers and hydraulic tappets operated the valves, while the cams were lubricated by an oil spray bar secured to the cam locating caps and supplied with pressurized oil. The oil filter housing was remotely mounted, equipped with flexible supply and return pipes. Cooling was facilitated by a combined water pump and thermostat unit with an 85-degree thermostat. The M70’s bore and stroke of 84 mm/75 mm resulted in a cubic capacity of 4988 cc, and it had a relatively low compression ratio of 8.8:1.

The M70 V12 Engine: A Legend in the Making

At the time, the electrical and engine management system of the M70 V12 was state-of-the-art. It introduced the use of EML fly-by-wire throttle, eliminating the need for cables between the engine and the accelerator pedal. Bosch Motronic 1.7 was employed, with two systems utilized, one for each bank. This approach involved two sets of plug leads, distributor caps, and crankshaft sensors. The intention behind this design was to ensure that even if one bank malfunctioned, the engine would still deliver a full 150 bhp, keeping the vehicle operational.

When it was launched in 1987, the M70 V12 produced 300 bhp at 5200 rpm, with 450 nm of torque at 4100 rpm. In comparison, the Mercedes 560SEL, with its 5547 cc V8, generated 275 bhp and 430 nm of torque. BMW was certainly on the right path, but did they surpass Jaguar? The M70 was smooth like a six-cylinder engine, whereas the Jaguar unit had a more mercurial nature and was notably quieter. It was an improvement, but deciding which was preferable proved to be a challenging question.

As the 750i continued to sell steadily, there was a need for a more powerful unit for the 850i. In 1993, the 850CSi was introduced, housing the 380 bhp S70 engine, which was developed in collaboration with BMW Motorsport. The S70 B56 was a hand-built 5.6 liter M70 engine with a displacement of 5576 cc achieved through an increased bore and stroke of 86mm and 80mm, respectively. The compression ratio was raised to 9.8:1, and the Bosch Motronic 1.7 management system was optimized to produce 380 bhp at 5300 rpm, along with 550 nm of torque at 4000 rpm. The cylinder heads received re-profiled camshafts, while the valves remained unchanged. However, production of the 850CSi was limited to just over 1500 cars due to non-compliance with US emissions regulations.

The M73 V12 Engine: A More Powerful and Efficient Evolution

In 1994, the original 750i was succeeded by the all-new E38 model, featuring the new 5.4 liter M73 engine. Prior to the E38 launch, this derivative was first installed in the 850i in January 1994 to ensure its readiness. Unlike the 5.6-liter engine, the bore and stroke were different, measuring 85mm and 79mm, respectively, resulting in a displacement of 5379 cc. The compression ratio was increased to 10:1 for improved efficiency. The power output was rated at 326 bhp at 5000 rpm, with torque increasing to an impressive 490 nm.

The M73 engine incorporated oil cooling jets for the pistons and featured an enhanced Bosch Motronic M5.2 system with knock sensors in the cylinder heads. Measures were taken to reduce friction, such as utilizing smaller diameter camshaft bearings and roller rockers from the new M43 four-cylinder unit. Additionally, softer double valve springs and lighter exhaust valves were employed, along with secondary air injection for emissions control. Steel tubular exhaust manifolds were chosen for their ability to heat up more quickly compared to cast iron types, further enhancing performance.

Why the BMW V12 Engine Is Still So Popular Today

It was a good engine, the M70 and its offshoots. Smooth, reliable and with impressive top end shove, it was also a little too fond of petrol and the Lexus LS400 of 1989 caused panic in Germany – the BMW V8’s would pretty much outpoint the old V12 on most counts. BMW would revive the V12 in later years with the E65 760i and it’s magic N73 and, whilst you’d deserve an Iron Cross for owning and feeding one now, consider that the first owner paid inn the neighborhood of $100,000 just so you or I can buy it now for peanuts. Try eBay, you know you want one.