There are a myriad of shotshell loads advertised as turkey loads these days. To get just a taste of the variety available, please see Joe Genzel’s article The Best Turkey Loads of 2023, Tested and Reviewed. That review focuses mainly on 12-gauge loads. If you were to add in all the sub-gauge variations plus all the handload possibilities, the options become almost limitless. But with such a wide variety of loads, how do we really know if any of them are adequately lethal for shooting turkeys? And how do we know if a given load is lethal or not to the outer range of responsible turkey shooting, which I consider to be 45 yards?

These were questions that a major ammunition company wanted a science-based answer to. So, way back in 1988 and 1989 as part of my consulting contract, the company asked me to design and run a controlled field test with statistically-sound sample sizes similar in methodology to the tests I was co-designing, running, administering, and publishing to objectively test steel vs. lead performance for taking wild ducks and geese (see my recent article Is Steel Shot Effective? Here’s What the Data Say After Decades of Testing). In order to be valid from a lethality standpoint, the test design required shooting live turkeys at measured distances common to turkey hunters. We would assess killing vs. wounding behaviors, pellet strikes, and pellet penetration performance data. We would not use such materials as plywood, chipboard, cardboard, or gelatin blocks for measuring pellet penetration. All of these materials have huge differences in densities, water content, and elasticity when compared to bird tissues.

Sample sizes would have to be statistically sound; no firing of one-shot samples (which are virtually meaningless). The test also had to include x-ray and necropsy results of the turkeys shot in the test. Supplemental head and necks used to gather additional turkey pellet strike and penetration data. Most importantly, the test had to be absolutely objective.

Methods

Here’s what we did. First, just as in the duck and goose tests, the turkey test design would have to be double-blind, meaning that neither the shooter nor the individuals compiling and analyzing the shooting data would know which loads were shot. Secondly, the sample size of the birds shot would have to be large enough to provide statistical confidence levels (intervals) of at least 95 percent (P ≤ .05). This means the sample size would be large enough that our findings would be valid, accurate, true, and repeatable 95 times out of 100. This required 10 live turkeys per load and another 25 heads and necks for each load at each relevant distance (25 body parts x 6 loads x 3 distances = 450 total heads/necks). We picked a Remington 1100 with a factory fixed full-choke, which was a commonly used combination for turkey hunting at the time. The turkey body sizes had to be representative of the wild birds actually taken by U.S. hunters. So we used live domestic tom turkeys (Meleagris gallopavo) that weighed 24 pounds on average. We used another 450 domestic tom turkey necks and heads from dead birds of the same average weight. We suspended the heads and necks at our measured distances.

The test loads were all 12 gauge options. We used 2¾-inch, 1¼ oz. steel loads at 1275 fps in shot sizes 5, 4, and 3. We also used a prototype 2¾-inch, 12 gauge, 1-5/8 oz. buffered Lubaloy (copper-plated) lead load in pellet sizes No. 6, 5, and 4 at 1250 fps. I developed the 1-5/8 oz. lead load for the ammo company and it has since become a standard production load. The shooting distances of the live turkeys was 35 and 45 yards. This meant 10 birds at each of these two distances for each of the best lead and best steel pellet sizes, which we chose based on penetration measured on the 450 supplemental heads and necks shot at 25, 35, and 45 yards.

The live turkeys were obtained from an Illinois turkey farmer. The supplemental heads and necks were obtained from a California turkey farmer and shot at Tule Lake National Wildlife Refuge in Northern California. X-rays were taken at a cooperating veterinarian office in Klamath Falls, Oregon. Each live turkey was tethered to a stake at a precisely measured distance. The aim point for both the live turkeys and the supplemental heads/necks was the fourth cervical vertebrae. Shots were made with the turkey’s head and neck facing to the left. Any wounded turkeys were quickly killed. After testing, all the turkeys were processed and donated for consumption.

We also did serious pattern testing with all the load variations. Patterns were taken in 10-round samples at 25, 35, 40, and 45 yards for each of the six loads tested (240 patterns) using the industry standard 30-inch circle drawn around the densest registration of the pellets after each shot was fired. We then counted the number of pellet strikes within the circle. We pattern tested two different Full chokes with constrictions of .685- and .695-inch. Those patterning results indicated about 5 percent denser pellet registration from the .685-inch Full, so that’s what we used throughout the test. The 450 supplemental turkey necks and heads fired upon provided 6,940 pellet strikes and penetration measures on the head and neck anatomies targeted. The sample sizes of the pattern testing provided confidence levels of 95 percent (P ≤ .05). The head and neck samples provided confidence levels of 99 percent (P ≤ .01).

Turkey Load Lethality Findings

Before you can understand our findings, you must understand how we evaluated the birds after they were shot. We separated shot birds into three behavior categories:

- B-1: Dead or immobile within 30 seconds

- B-2: Alive and mobile, but retrievable

- B-3: Wounded, able to run off

Examining the necropsy and x-ray data for the live bird shooting revealed clearly that all turkeys which exhibited B-1 behavior always experienced pellet strikes on the much smaller target area of the skull and cervical vertebrae, along with the overall head and neck surface area. And critically, the minimum penetration depth of those pellet strikes on the skull and cervical vertebrae on the B-1 birds was sufficient to pass completely through those dense bone tissues to puncture the brain and/or spinal cord.

Lethality Lessons at 25 Yards

Necropsies and x-rays revealed both of the loads and all six of their pellet sizes produced ample patterns to provide the needed pellet strikes and sufficient penetration on the skull and cervical vertebrae to B-1 kill 100 percent of the turkeys shot at that distance.

Lethality Lessons at 35 Yards

The same level of 100 percent B-1 lethality performance occurred with both of the loads and all six of the pellets tested. Necropsies and x-rays revealed the same location of pellet strikes (skull and cervical vertebrae) and the same depth of penetration associated with B-1 behavior as at 25 yards. But at 35 yards, fewer total pellet strikes on both critical areas were found to have occurred. In other words, the number of strikes on the critical skull and cervical vertebrae areas found at 25 yards were actually in excess of what was needed for a B-1 kill.

Lethality Lessons at 45 Yards

B-1 bagging performance failed to occur 100 percent of the time with either of the two loads and six pellet sizes tested. The x-ray and necropsy results revealed why.

The best performing load was the No. 5 Lubaloy (electrolysis copper-plated, high antimony lead shot) pellets. At 45 yards it produced nine out of 10, or 90 percent, B-1 lethality and one out of 10, B-2 (mobile but retrieved). Both No. 6 and No. 4 lead produced unacceptably low (failed) levels of B-1 bagging at 45 yards. They produced well below 70 percent B-1 results. With these two lead pellet sizes fully 30 percent of the turkeys shot at 45 yards were classified as B-3 (wounded and able to run off). Necropsy revealed the lead 6’s failed to deliver the needed penetration and the lead 4’s failed to produce an adequate number of pellet strikes on the turkey’s critical skull and cervical vertebrae areas.

Of the three steel loads tested at 45 yards, No. 4 steel performed best delivering eight out of 10 B-1 birds and two B-2 birds, for 80 percent B-1 lethality. The No. 5 and No. 3 steel pellets failed similarly to the lead No. 6’s and 4’s. The steel No. 5 and No. 3s delivered below 65 percent B-1 lethality with a 35 percent B-3 wounding rate. At this distance, necropsy revealed the steel 5’s failed to deliver sufficient penetration and the patterning density of the steel 3’s failed to produce sufficient pellet strikes on the critical turkey skull and cervical vertebrae areas.

What the Data Tell Us

From the shooting of both the live turkeys and the supplemental heads and necks and their x-ray and necropsy, which provided thousands of pellet measures, we know what the minimum number of pellet strikes and penetration necessary on the skull and cervical vertebrae of a typical large tom turkey to produce B-1 bagging out to 45 yards. From the hundreds of patterns shot and counted, we know the pattern-count and pattern density values needed to produce the minimum number of pellet strikes on the skull and cervical vertebrae. That information is outlined here:

Lead Pattern Density

- B-1 results at 45 yards with lead turned out to be a minimum average of 207 pellets in the 30-inch circle.

- Minimum average of pellet strikes in the head and neck: 6.8

- Minimum average of pellet strikes in the skull and cervical vertebrae: 2.8

Lead Penetration

At 45 yards it took at least a No. 5 (.120-inch) high antimony lead pellet weighing an average of ~2.57 grains when launched at 1250 fps to be capable of penetrating completely through a turkey’s skull and cervical vertebrae to produce B-1 bagging.

Steel Pattern Density

- With the steel pellets we found it took a similar 30-inch pattern average 200 pellets at 45 yards of No. 4 steel for B-1 results.

- Minimum average pellet strikes in the head and neck: 7.6

- Minimum average of pellet strikes in the skull and cervical vertebrae: 3.6

Steel Penetration

A No. 4 steel pellet weighs about 2.28 grains and was found to be the minimum weight necessary when launched at 1275 fps for this hard, non-deformable pellet type to penetrate at 45 yards completely through the skull and cervical vertebrae of a turkey to produce B-1 bagging.

How to Test Any Turkey Load

Using these findings here’s all you have to do now to accurately and scientifically measure and determine if any turkey load regardless of gauge, shell length, and pellet type/size you propose to hunt with is truly lethal for turkeys out to 45 yards. Proceed as follows:

Select the Right Pellet Size

First you must select the correct minimum pellet for adequate penetration. That’s a No. 5 lead pellet and or No. 4 steel pellet if you want to shoot turkeys at 45 yards. I’m currently testing TSS loads but that data won’t be complete for some time.

If you select a lighter weight of either soft or hard pellet type, stop right there as you will NOT have lethal penetration at 45 yards. Lighter pellets will likely penetrate out to 35 yards and certainly at 25 yards, but will produce wounded birds at 45 yards.

Pattern Your Load and Choke

Now you must pattern test your chosen load at 45 yards. The right way is the industry standard of firing one shot at one 40-inch by 40-inch pattern surface (metal plate or paper sheet ) and then drawing a 30-inch diameter circle around the densest registration of pellet strikes. You must then count (not just eyeball) all the pellet strikes that fall in or on the circle. Then, because all the variation in every shotshell load is so great that no two rounds ever pattern the same, you must fire a minimum of five shots at five separate sheets of paper, count them all, and average them.

What you are looking for is a minimum pattern count average of 200 strikes ending in the 30-inch circle. That will ensure enough pellets end up striking the critical skull and cervical vertebrae of your turkey. If you get a denser pattern count than 200 at the distance you believe you will be shooting most of your turkeys, so much the better. Always remember: It takes both pattern density and proper penetration to kill a turkey (or any game bird).

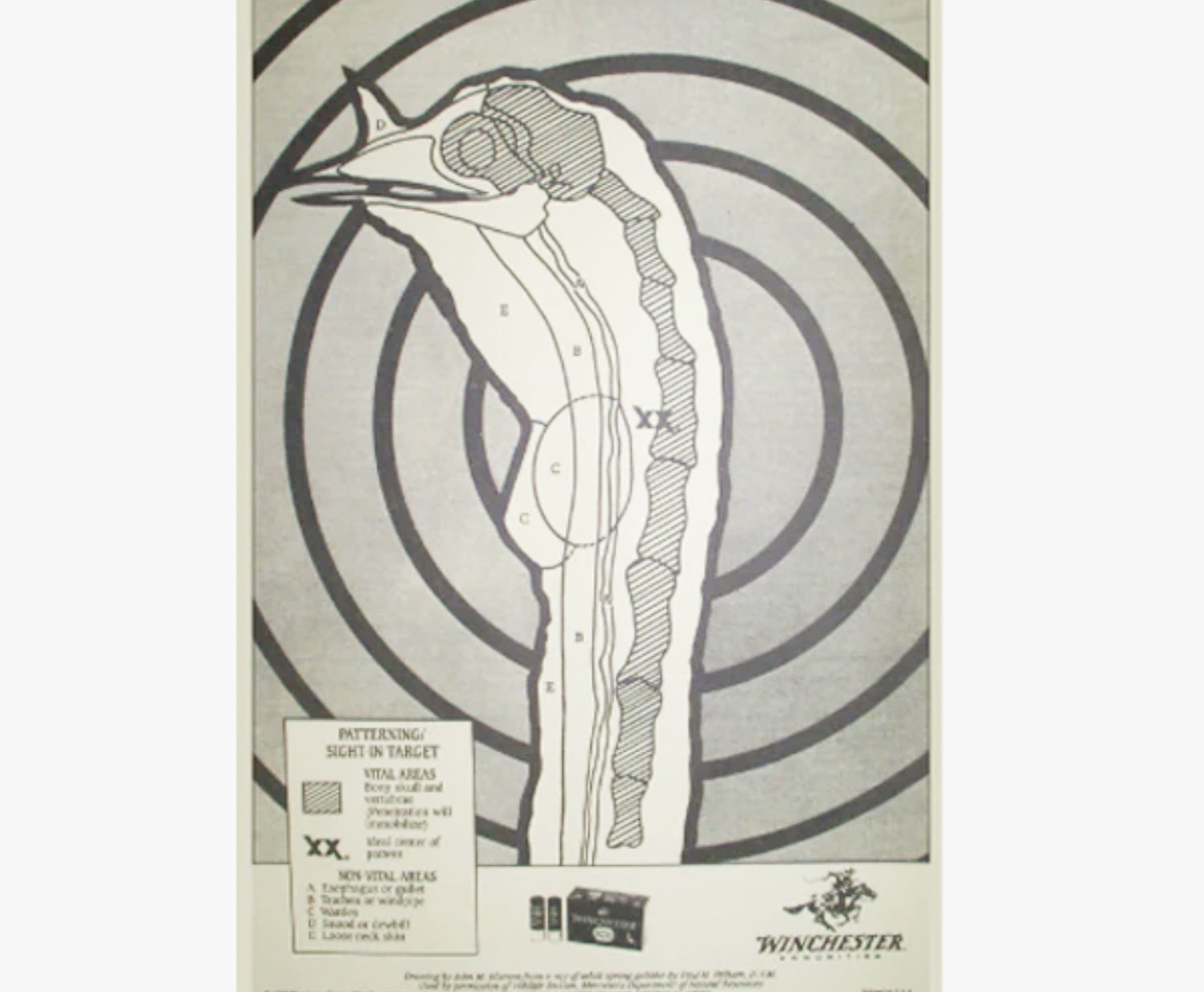

Or Pattern With a Turkey Target

An alternate patterning method is to purchase and use the Winchester copyrighted Turkey, Head and Neck Target Sheets. Using this turkey patterning aide will take much less time to determine a sufficient pattern with your chosen load and choke. The target sheets contain the head and neck drawing of a turkey facing to the left with the vital skull and cervical vertebrae areas clearly highlighted. The whole drawing is anatomically correct and real-live size. The correct aim point is marked with an XX on the fourth cervical vertebrae.

Shoot the target and determine if you are obtaining the minimum average necessary of 2.8 strikes with No. 5 lead pellets or 3.6 No. 4 steel on the skull and cervical vertebrae in the drawing. You will still need to shoot a minimum of three shots at three targets, but five shots at five targets is even better.

So that’s it. Now you have a method to determine turkey load lethality out to 45 yards no matter what brand you’re shooting. Just because a load is advertised as a turkey load with a longbeard drawn on the box does not make it so. You should test the load through your choke to know if it is lethal. And I assure you, you will soon learn that many loads are not lethal to 45 yards on turkeys. Taking the small amount of time to do the above simple testing will ensure that you go afield responsibly with a scientifically measured turkey load knowing its max lethal distance. The end result will be hunters producing a significantly lower number of wounded and lost turkeys afield.