GM has built a strong argument around the idea that one specific battery cell format, co-developed with LG, is a key for the company realizing certain economies of scale as it ramps up EV production.

But recent reports have suggested that GM is shopping around, and may be considering a shift to cylindrical cells for some upcoming vehicles. And while remarks this week from the company’s top executive didn’t confirm that, they suggested that the company may no longer be as focused on that singular solution as it was two years ago, when it revealed its Ultium propulsion strategy for scaling up EVs.

In a conference call with financial analysts held Tuesday, GM CEO Mary Barra confirmed that yes, the company is looking at other formats—as it has all along.

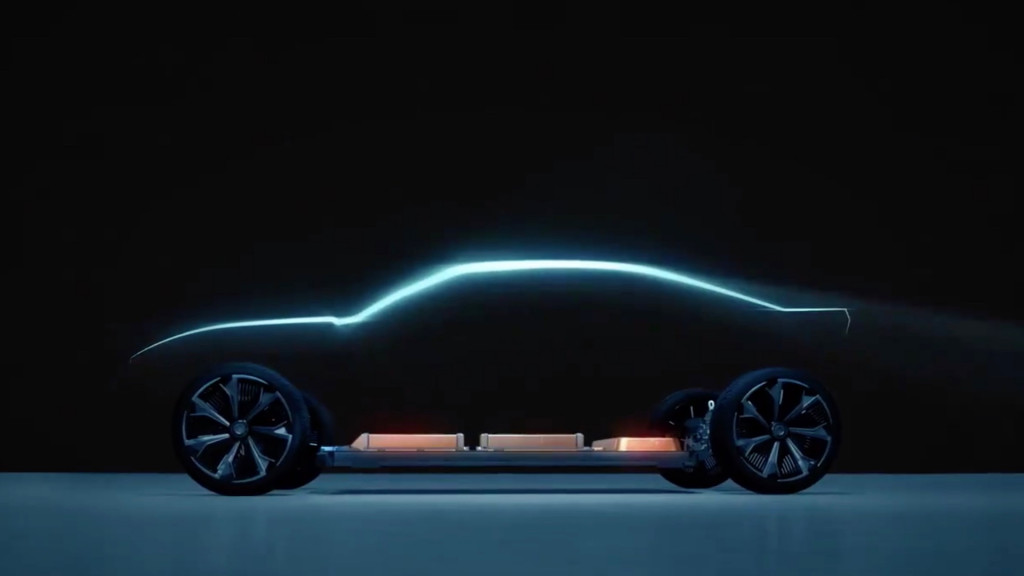

General Motors’ BEV3 platform and Ultium batteries

“One of the strong points of the Ultium platform is that it’s chemistry-agnostic and it can take pouch, prismatic, or cylindrical cells,” Barra said. “And so we can look to what is going to be the right battery for the specific vehicle from a performance perspective, so we have that complete flexibility.”

Barra called the report of a commitment to cylindrical cells “speculation.” But she did comment a bit more on the idea at several points.

“Our team has been working and looking at all three cell form factors for a while,” Barra added, in response to another follow-up question on the cells. She pointed to how GM is currently installing prismatic cells into several Ultium-based vehicles as built in China—the Cadillac Lyriq and at least one Buick model.”

One to rule them all

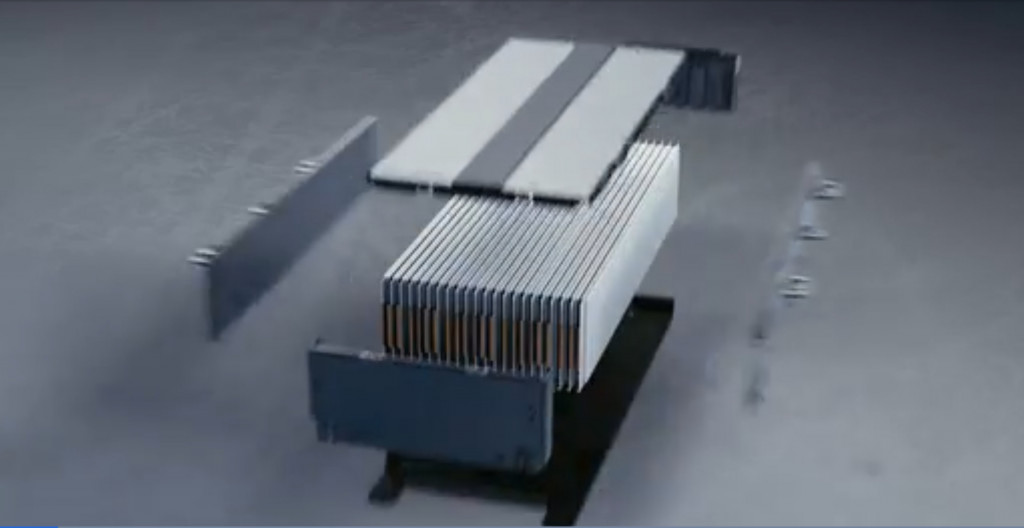

In the U.S., GM has emphasized that its single large-format pouch cell can be configured horizontally or vertically into modules, allowing single- or double-layer packs suitable for carrying six to 24 modules. That could underpin everything from mid-size cars and sports cars, or crossovers like the $30,000 Chevrolet Equinox EV, on up to gigantic trucks like the GMC Hummer EV and upcoming Chevy Silverado EV.

2024 Chevrolet Silverado EV Work Truck prototype

GM also confirmed in its update that it’s still planning to ramp up production of the Silverado EV WT (Work Truck) for commercial customers this spring.

Separately GM and Honda are also working together on an Ultium platform suitable for compact cars, with the first vehicles due by 2027.

GM has also emphasized that the Ultium platform’s industry-first wireless battery management system will make the substitutions of modules packed with different chemistries or cell types easy to integrate without having to completely redesign the pack.

Possible electric Chevrolet Camaro in GM Ultium teaser video

There are some real packaging drawbacks, though. Its cell format—a larger pouch cell than any other automaker is using—has created some particularly tall pack form factors, though. A shift to cylindrical cells might help lower their profile for passenger vehicles and make the vehicles easier to design for peak aerodynamics and driving range.

What about economies of scale?

Financial analysts in GM’s quarterly call didn’t take the question to the next step—by pressing Barra, perhaps, on how such a decision might affect the cost of the cells or the horizon for getting to economies of scale, which the company hasn’t shied away from talking about in the past. GM had said a couple years ago that the Ultium strategy’s large-format NCMA pouch cell—co-developed between GM and LG—was “priceless” because it allowed the automaker to keep driving down cost with economies of scale on the way to parity with combustion vehicles later this decade.

The company has also teased that it’s been running durability testing on its “next-gen Ultium” cells that might be phased in for the later part of the decade—potentially subbed in easily with the flexibility of the platform. Those might further aid affordability while giving the company the choice to prioritize cost or a 600-mile range.

GM Ultium battery

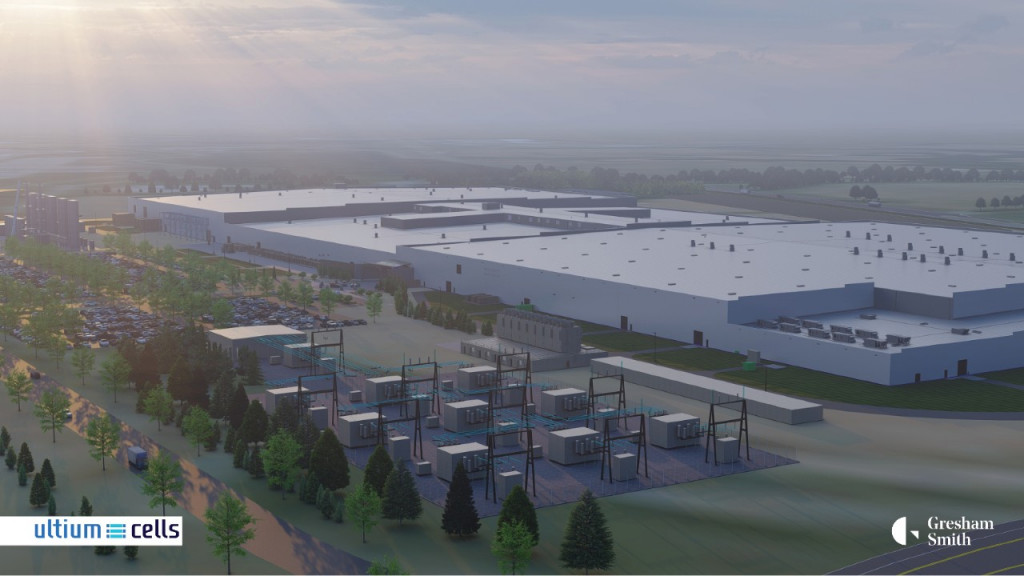

In Tuesday’s call, Barra called LG Energy Solution “an incredibly important partner” to GM, and reported that the companies are working well together on the launches of plants in the Lordstown, Ohio, one in Spring Hill, Tennessee, this summer, and one in Lansing, Michigan to follow in 2024.

“And we are going to need a fourth plant and more plants beyond that…right now, there’s nothing that’s really changed in our plan to have battery manufacturing capability here in the U.S. and broadly, in North America as well,” Barra said.

GM may be playing wait-and-see with that fourth plant for several potential reasons. Each of three upcoming battery plants aims for 37 to 40 gigawatt-hours annually. Once ramped up, they would provide enough capacity for well over a million EVs a year.

Conceptual drawing of Ultium Cells plant in Tennessee

For whatever reason, Barra didn’t reiterate that the fourth battery plant would produce the same cell format that it’s said is key for economies of scale.

Whether this means the fourth plant might build cells in a different—perhaps cylindrical—format, or whether GM is merely delaying the decision depending on the uneasy implementation of the EV tax credit and its domestic sourcing rules, it seems the automaker is keeping its options open.